🔥 10 Easy Things to Check When Troubleshooting a Furnace Gas Valve

This article is written in order to help a homeowner troubleshoot a bad furnace gas valve with only a few inexpensive tools that could be purchased from your local hardware store.

In order to help you properly troubleshoot your natural gas or propane furnace, I’m going to start by explaining the furnace’s heating sequence of operations.

Once you understand the process a furnace goes through before it fires up the burner tubes you’ll be able to determine whether a gas valve replacement is needed or not.

Table of Contents

🔥 A Furnaces Sequence of Operations

Professional HVAC technicians know this process like the back of their hand.

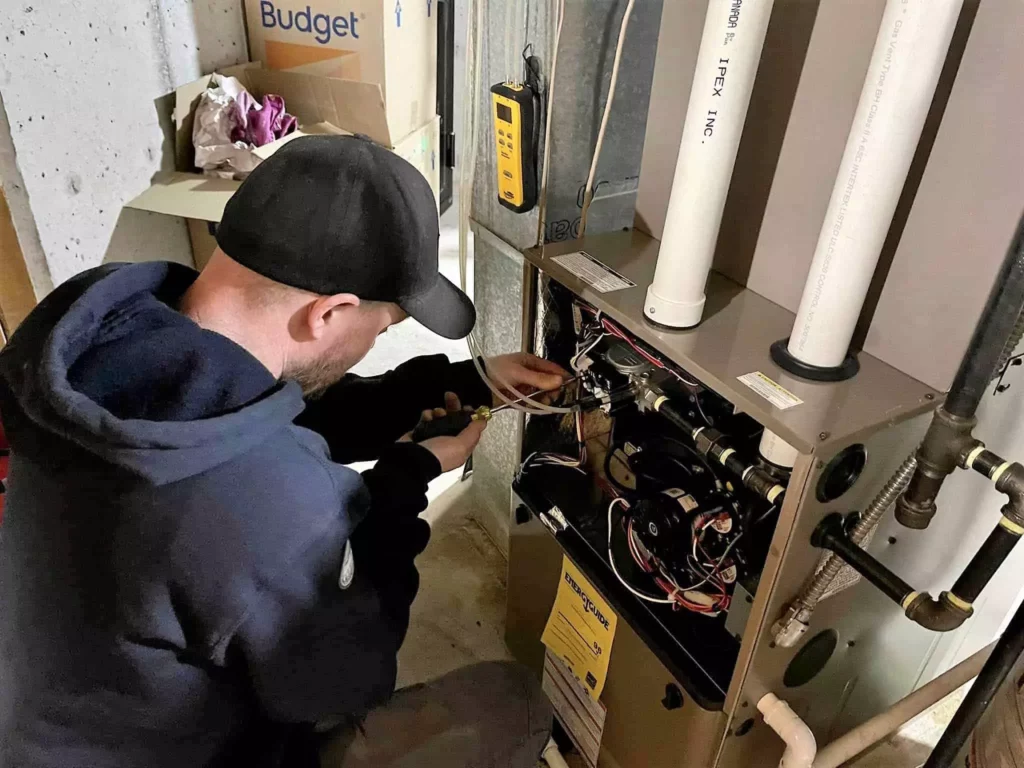

They have quality tools and the experience to troubleshoot faulty gas valves quickly and cost-effectively.

With that said, I can understand that many homeowners want to troubleshoot and repair furnace problems themselves to try and save money, and that’s why we’re here.

So, ensure you understand the sequence below and then continue to the next section.

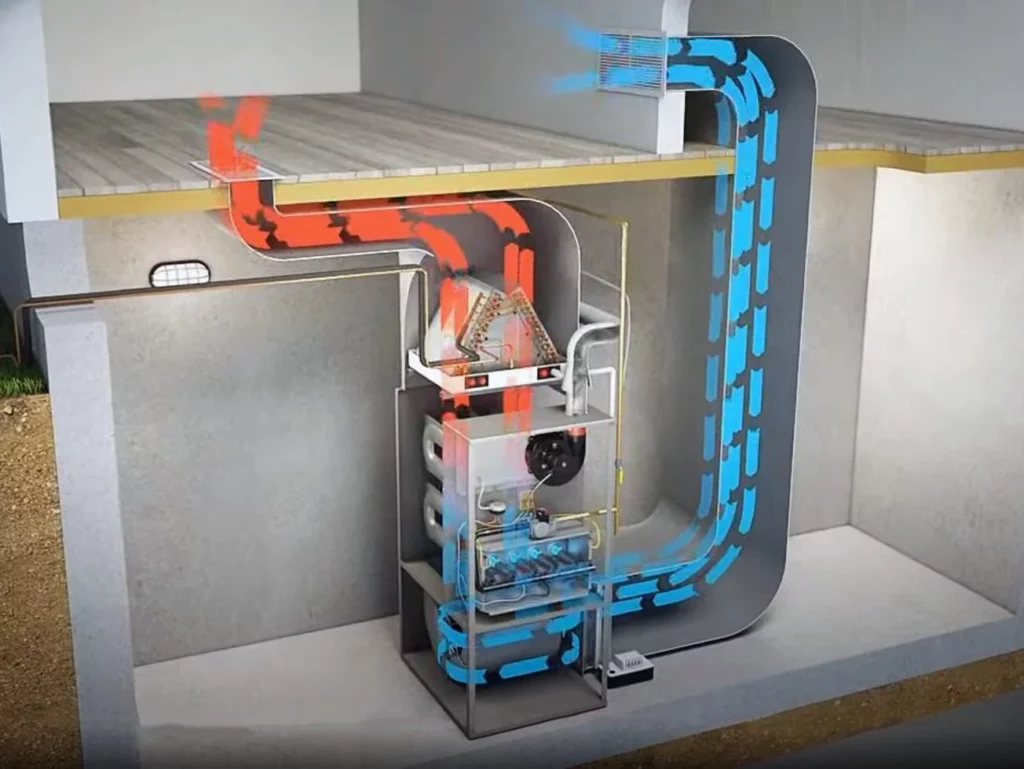

- The electrical panel sends power to the furnace control board.

- The thermostat sends a 24-volt signal to the furnace to turn the heat on.

- The control board turns on the exhaust/inducer motor.

- The control board sends a 24-volt signal through the safety circuit, which includes a pressure switch that senses that the inducer is properly exhausting the fumes from the heat exchanger.

- With the safety circuit sending a successful signal back to the control board, the signal to initiate the ignitor and the gas valve gets sent.

- As the gas valve opens, the ignitor either glows orange or sparks to light the flame.

- Now that the flame is lit, the flame sensor will recognize that it’s lit and that it’s safe for the gas valve to stay open.

- Once the heat exchanger warms up, the blower motor kicks in and sends the warm through the ductwork and out the registers.

Using your Eyes and Ears to Determine if the Gas Valve is the Problem.

Ok, so let’s start by cycling the power to the furnace off and then back on.

This will reset any control board lock-outs and allow the furnace to complete its sequence of operations.

Ensure the thermostat is set to heat and the temperature setting is above the temperature in the space.

Now listen to the furnace.

The inducer motor will start running, then the ignitor will either spark or glow orange, and then the gas valve will open, the flame will light, and then the blower will start.

If the sequence doesn’t make it to the flame lighting, you either have a bad control board or a bad gas valve.

Troubleshooting a Furnace Gas Valve

For this step, you will need an electrical multi-meter, some Allen keys, and a manometer.

With tools by your side, you’ll need to confirm that 24 volts is coming from the circuit board to the gas valve terminals.

When a gas valve gets the 24-volt signal, you should hear a little clicking noise the internal valve makes, if you don’t hear that, then you could have a bad gas valve.

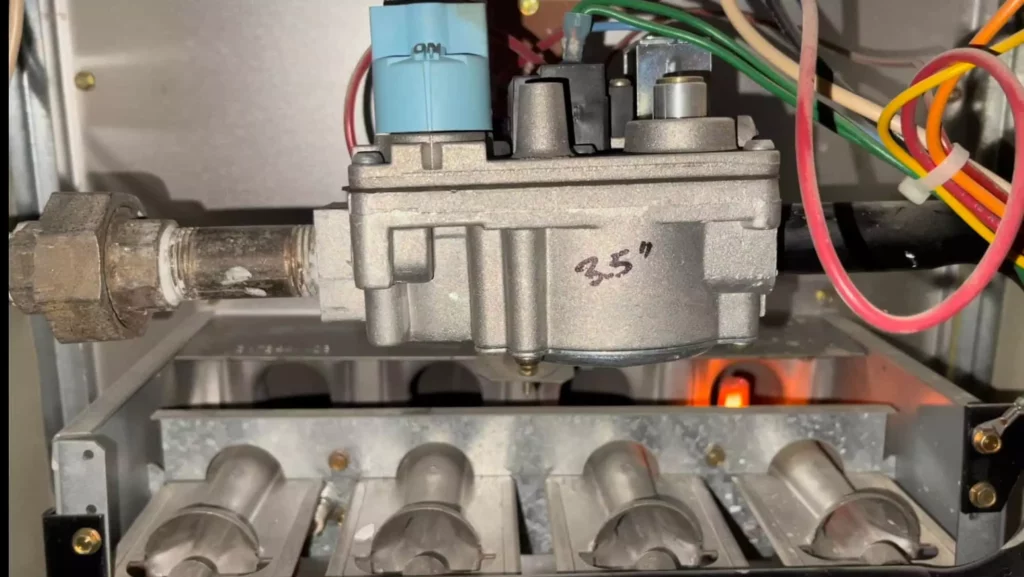

If you don’t have 24 volts, something else is wrong, but if you do, you’ll need to confirm that you have gas pressure coming into the furnace gas valve (it should be between 7″ WC and 11″ WC).

If you don’t see that gas pressure, you’ll need to check to ensure that all your gas line isolation valves are open and that the gas meter isn’t shut off or locked out.

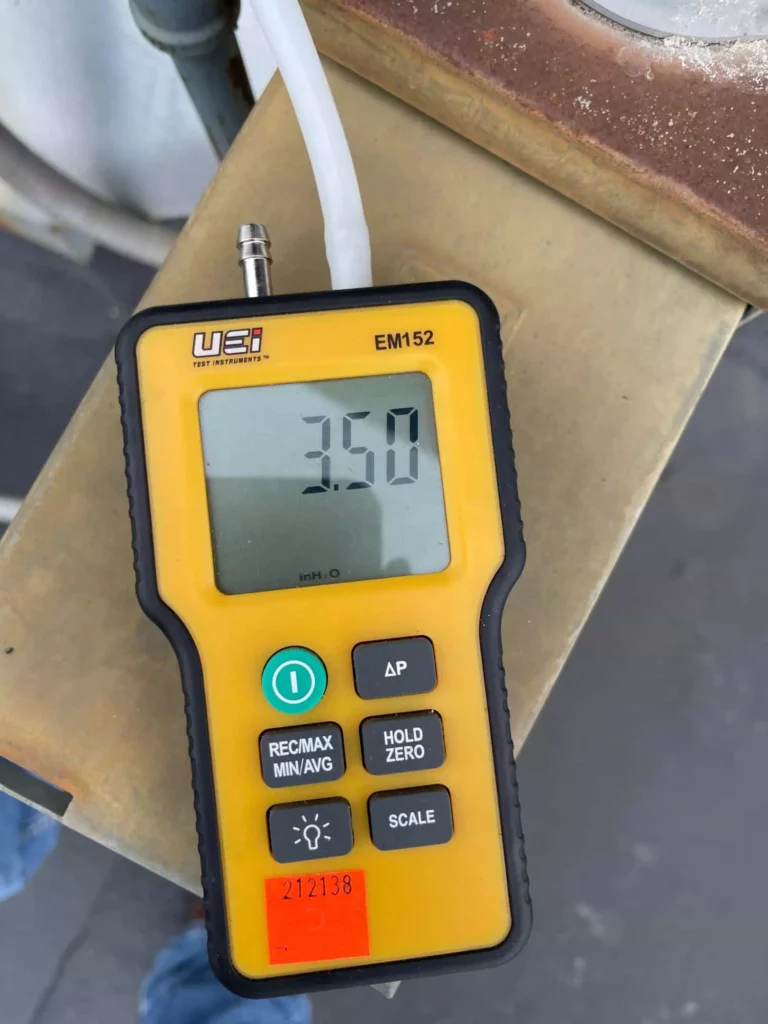

If you do have that pressure, and you do have 24 volts to the gas valve, then you should have gas pressure leaving the valve (usually 3.5″WC).

If you do have that pressure, but it’s not lighting, then the problem is most likely the ignitor, but if you don’t have that pressure, then you do have a bad furnace gas valve.

Check these other six things before condemning furnace gas valves:

- Check that none of the wires are burned, cracked, or frayed. If they are then, you’ll want to replace those wires and then continue checking this list.

- Check the gas pressure coming into the gas valve, it should be between 7″ WC and 11″ WC.

- Check that you have 24 volts going to the furnace gas valve; if you don’t, then there’s another problem.

- Check that the burner orifices aren’t blocked or plugged. This could stop the gas from getting to the flame ignitor. You can confirm this by checking the gas pressure leaving the gas valve. You can clean them with a paper click or similar wire by poking the orifice.

- If the flame comes on for a few seconds but doesn’t stay lit, then the problem isn’t the gas valve; it’s most likely the flame sensor.

- The flame might be coming on for a few seconds but then shutting off. Is there a dropout of voltage or gas pressure to the gas valve? That’s something to check for sure. And you can do that by putting a “T” fitting in line with the hose to connect to your manometer. Check the inlet and the outlet side to see if the pressure drops on either side of the valve.

🙋 What Does Water Column (WC) Mean?

In the context of HVAC, the term “water column” typically refers to a column of water that is used as a reference or measurement point.

This can include a column of water in a pressure gauge or other device used to measure the pressure of the water in the HVAC system.

The height of the water column is often used to indicate the water pressure in the system.

A higher column indicates a higher pressure, and a lower column indicates a lower pressure.

This information can be used by HVAC professionals to diagnose and troubleshoot problems with your furnace.

🔥 How to Change Out a Furnace Gas Valve Safely

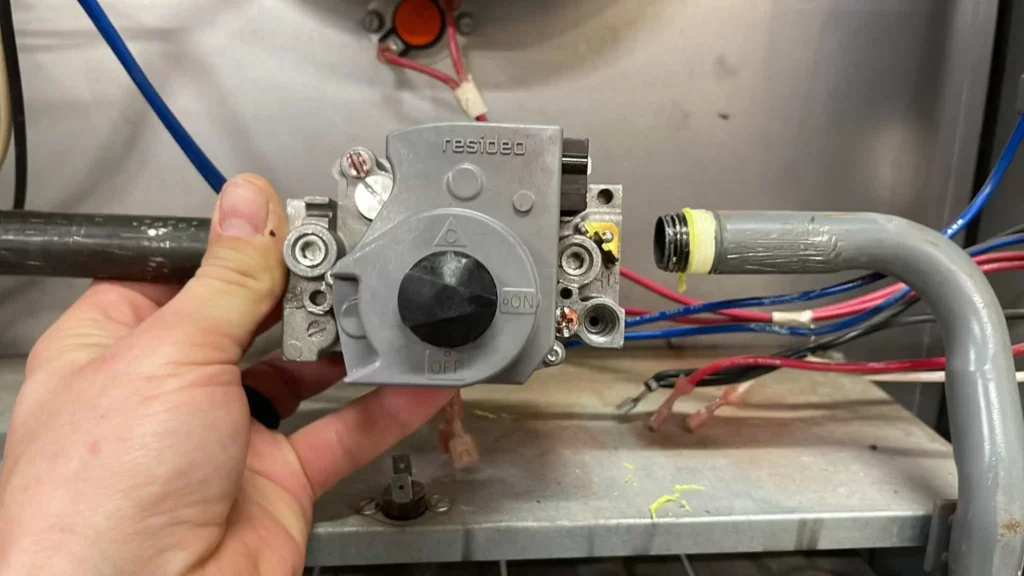

STOP: If you confirm that the furnace gas valve is bad and decide to change it out, please know that gas leaks are a serious issue.

We highly recommend having a professional HVAC technician perform this part replacement.

If you decide to do it yourself, just take precautions to not bend the manifold or overtighten the gas piping.

Once everything is changed, you should perform a leak test on your gas piping following your local safety authorities’ guidelines.

Once you’ve changed out the furnace gas valve, you’ll want to confirm that the pressures are set according to the furnace manufacturer’s specifications.

🔥 How to Check the Gas Pressure on a Furnace Gas Valve

I described it briefly above, but to recap, you’ll need some Allen keys and a manometer.

Start by closing the gas shut-off valve and then removing the Allen screw on both sides of the gas valve.

Attach the manometer tubes to both ports and then open the gas shut-off valve.

You should have between 7-11″ WC going into the gas valve, and if the furnace gas valve opens then you’ll have 3.5″ WC leaving the gas valve.

🔥 How to Check the Furnace Gas Valve for 24 Volts

Take your electrical multimeter and set it to voltage.

If you have two wires going to the gas valve, place the multimeter leads on each.

If the thermostat is calling for heat and the inducer motor is running, you should have 24 volts.

If you can’t get the multimeter leads connected to the gas valve, then you can remove the wires from the gas valve just to confirm whether you’re getting voltage or not.

✅ PRO TIP: Take a photo of the wire connections before removing them just to ensure that you put the wires back in the right spots.

🔥 Where to Buy a Furnace Gas Valve

Again I would like to emphasize our recommendation to have a professional HVAC contractor perform this work for you.

Since labor costs and replacement costs can be so high, we can understand that you might do this yourself.

So, contact the manufacturer with your equipment model and serial numbers and ask them for the part number for your gas valve.

While you’re at it, ask the manufacturer to check to see if your furnace is still under warranty.

Then contact the manufacturer’s local supplier to get pricing and availability.

If there isn’t a local HVAC supplier for that manufacturer, then you’ll have to do a little more searching, but if you’re a gambler, then Amazon might work for you…emphasis on might.

🙋 Should Furnace Gas Valves be Changed by an HVAC Contractor?

The simple answer is yes, but many homeowners will do what they’re going to do.

We recommend reading multiple articles like this, watching multiple YouTube videos, and buying all the recommended tools.

🔥 What’s Next for Furnace Troubleshooting?

We have an in-depth article on the top problems and solutions for furnace repairs.

So, if this article doesn’t solve your furnace woes, then head there and give it a thorough read.

For great information on managing your HVAC system in winter, check out our other furnace articles.