HVAC systems have many complex components to provide heat and cool air when needed.

When your furnace malfunctions, locating the exact cause or knowing what to replace can be challenging.

It is advisable to call a professional HVAC repair service as the first step to avoid the risk of personal injury or damage to your system.

That said, there are several diagnostic tools you can use to help point the HVAC technician in the right direction if you feel comfortable doing the following checks.

⚡ Want to know what tools professional electricians use?

Check out the following article: The Electrical Tools Every New Electrician Should Have

Although the problem could originate in your electrical system, not your furnace, so check your HVAC system first for irregularities.

Table of Contents

The Most Common Causes of Furnace Malfunctions

🔧 Loose Wiring

Furnaces are prone to a bit of shaking and rattling during operation.

Occasionally inner wires come loose to the point that they cause the unit to short circuit.

Scheduling regular maintenance with a professional HVAC technician mitigates this issue.

🔧 Clogged Air Filter

HVAC filters accumulate dust and debris over time, compromising heat levels and indoor air quality.

The buildup of dirt and dust clog the filter and cause the blower motor to overheat and run the risk of catching fire.

🔧 Dirty Fuse

System components accumulate dirt and grime, causing them to operate at a compromised level.

🔧 The Wrong Fuse

If the installed fuse is too small for the HVAC system in your house, a short circuit is inevitable.

🔧 Failing Starting Capacitor

Once diagnosed, a capacitator is a simple, inexpensive fix.

🔧 Blower Motor Issues

A faulty blower motor can also blow a fuse. This is something you will want to replace.

If none of the scenarios above apply to your system, then the problem may lie within your furnace control board.

What Is a Furnace Control Board?

The control board, also known as a furnace circuit board, is the mastermind of your furnace operation.

Circuit boards regulate all the furnace components, including the gas valves, ignition, blower motor, and flame sensor.

Signs of a Bad Furnace Control Board

Symptoms of a failing furnace control board include illuminated warning lights on the furnace diagnostic system and difficulty regulating room temperature, even when the thermostat registers a consistent reading.

A malfunctioning fan blower control or hot surface ignitor is more common than control board issues, though it creates similar problems.

Types of Control Boards

🔦 Gas Furnace Control Boards

This type of board is a simple ignition control board usually found in older units, which tend to be less energy-efficient.

It controls the operation of the gas valve, ignitor, and flame sensor.

🔦 Integrated Furnace Control

The more common furnace circuit board, at least in newer units, is the integrated furnace control board.

This board provides the same functions as the gas furnace control board and also controls the furnace blower.

🗝️ What Is the Life Expectancy of a Control Board?

In a perfect world, a circuit board would last as long as the furnace itself, and sometimes they do.

However, the aging process affects many parts of a furnace control board differently, any of which may decline from wear and tear.

Due to the standards set by the manufacturers when constructing these circuit boards, performing any repair to the board is only a temporary solution.

In such cases, your circuit board will need to be replaced.

How to Access and Test Your Furnace Control Board

Before you begin, you should have the following supplies ready:

- Voltage meter – necessary to determine whether your board is bad

- Electrical tape – to temporarily hold your furnace door open

- Screwdriver – needed to remove the access panels

Take the following steps to determine whether you have a faulty circuit board:

🧰 Examine the Furnace Diagnostics

Most furnaces have a diagnostic indicator built into the access panels.

They are encased in glass or plastic and have LED lights that blink to indicate the functionality of the furnace components.

Check your furnace manual on how to access and read the LED light indicator.

If you see blinking lights, compare what you see to the error codes listed in the instructions.

If the diagnostics show errors such as low voltage, your control board is likely on the fritz.

🧰 Take Off the Access Panels

There are usually two panels that house the interior components of the furnace and the control panel.

Using a screwdriver if needed, remove both panels.

🧰 Tape Down the Door Switch

To deliver electricity to the furnace, the door switch must be held down.

🧰 Examine the Control Board Indicator Light to Confirm Electrical Power

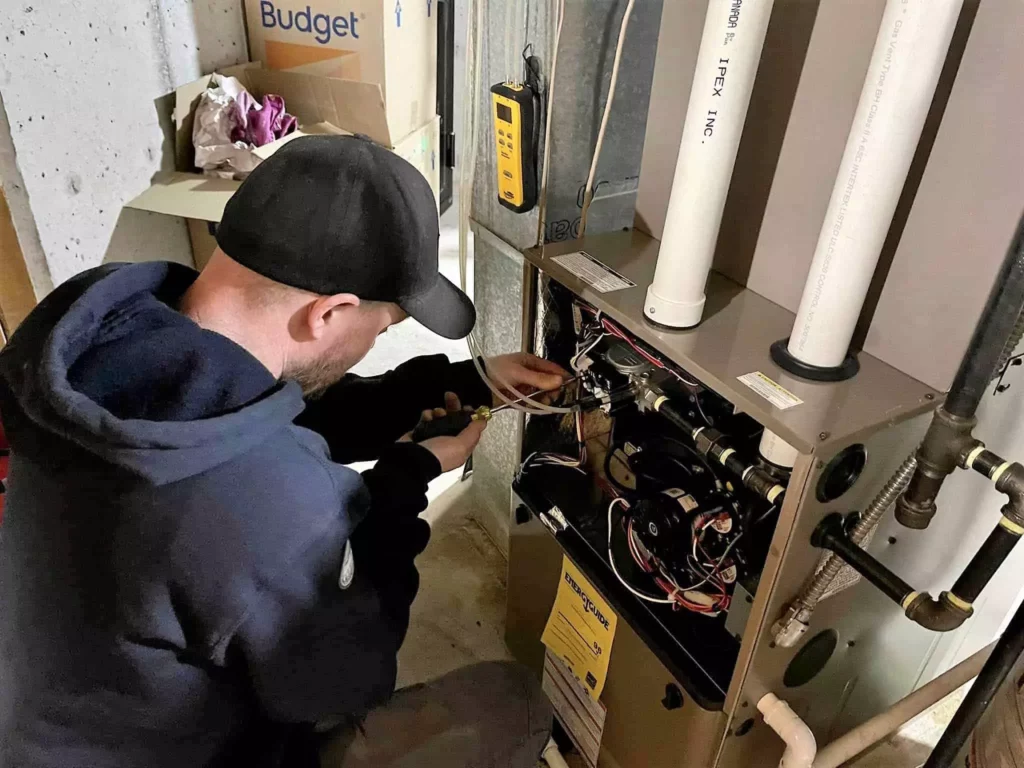

The control board can be found at the front of the blower and at the rear of the lower access panel. (See image above).

It is easy to identify, as several wires are running through it.

If the control board has an LED indicator light, it will be easy to determine whether electricity reaches your circuit board.

If you do not have an indicator light, follow the steps below to test the power flow of each component.

Your voltage meter is necessary to complete the following steps.

🧰 Step 1: Locate the Common Wire on the Transformer

The transformer is a separate square or rectangular unit that is attached to the furnace with screws.

The information about the common wire should be printed somewhere on the transformer box (look for the abbreviation “COM”).

The transformer has four wires attached to it: two of high voltage (120 volts) and two of low voltage (24 volts).

The two high-voltage wires are usually black and white. The common wire is usually the black high-voltage wire.

🧰 Step 2: Perform a Control Board Power Test

The line voltage is the wire running between the control board and the door switch.

Hold your meter leads against your common wire and your line voltage.

🧰 Step 3: Perform a Transformer Power Test

As the name suggests, the function of the transformer is to transpose the power coming from the high voltage wires from 120 volts to 24 volts.

Test the high voltage wires by touching the meter leads to each wire. Your meter should give a reading of 120 volts.

Follow the same steps with the two low-voltage wires. Your meter should give a reading of 24 volts.

If you don’t get a 24-volt reading on the low voltage wires, it means that your transformer is not converting the voltage from 120 to 24 and is most likely the source of the problem.

If you get an accurate reading from all the wires in the transformer, you know that the problem lies somewhere other than your transformer. Continue to the next step.

🧰 Step 4: Perform a Power Test on Your Molex Plug

The Molex plug connects directly to the control board. Follow the low-voltage wires to the Molex fixture.

Position the meter leads at the intersection of the plug and low-voltage wires. You should get a reading of 24 volts.

🧰 Step 5: Perform a Power Test on the Terminal Strip

You will recognize the terminal strip by the five wires of varying colors that line the edge of the furnace circuit board. Each colored wire has a corresponding letter.

Locate the “R” and “C” wires and touch them with the meter leads. Once again, you should see a reading of 24 volts.

If you perform these steps and confirm that your power connection is flowing properly from the line voltage to the Molex plug via the transformer and out through the terminal strip, you can rest assured that your control board is in good working order and won’t need to be replaced.

Should you run into issues down the road, you know what steps to take to diagnose the problem.

Please be advised that heating and cooling systems are complex machines with multiple working components, so be sure to stick with what you know.

Protect your investment by only allowing licensed, insured HVAC technicians to perform complex repairs.

Contact Your Local HVAC Professionals

Phyxter HVAC Services connects homeowners and businesses to the industry’s best Contractors and HVAC techs.

With access to a network of five-star-rated contractors, state-of-the-art equipment, and the ability to service all brands, our goal is to exceed our customers’ expectations at every turn.

Check out our page on Furnace Services or Electrical Services for more information, or check if Phyxter services your local area.

Make the most of your money and get the right professional advice the first time.

Want to learn more about your home’s heating system? Feel free to check out our other heating articles!

Related Reading: What is a Furnace Burner and Why You Should Keep Them Clean