If your home’s current duct insulation seems to be peeling, sagging, or splitting at the seams, it may be time to replace it.

Replacing this duct insulation will improve energy efficiency, lower utility bills, and help keep your home comfortable throughout the heating and cooling season.

Although patching up seams, gaps, and joints in your current duct insulation would most likely do the trick, it may not be a bad idea to replace this insulation in its entirety.

Especially if your HVAC system is located in the attic, where hot summer or freezing winter temperatures can have an adverse effect on your HVAC ductwork.

Table of Contents

⭐ What Are the Different Types of Duct Insulation?

Duct insulation can be made from various materials and come in many shapes, sizes, and forms. Common types of duct insulation include fiberglass, aluminum foil, rockwool, and XLPE.

Each type of insulation provides unique advantages and disadvantages that must be considered when deciding on a suitable material for your home.

From insulating against heat loss to preventing condensation buildup, each option offers something different that should be considered before making a purchase.

Here are three common types of duct insulation.

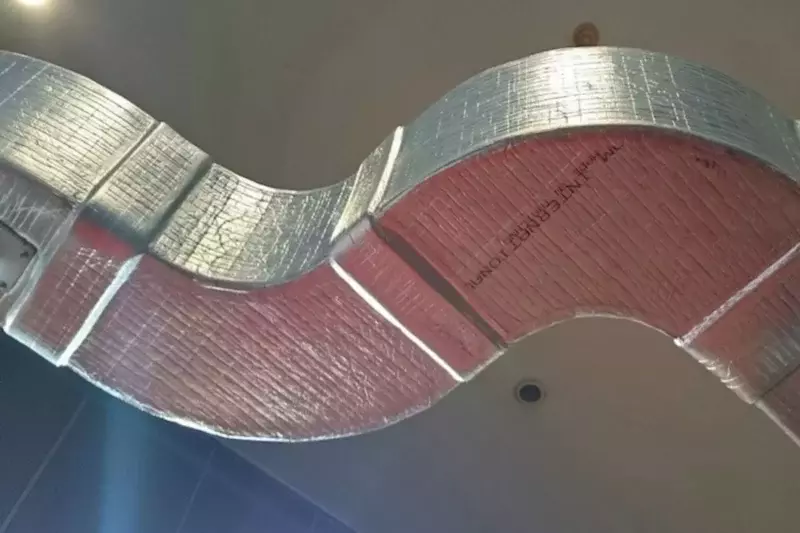

🔧 Aluminum Foil and Fiberglass Insulation

Fiberglass is the part that actually insulates.

However, it is held together by the aluminum foil backing.

This type is commonly used on round or square duct plenums, and branch runs.

Each piece can be custom fit for a tight wrap, with duct mastic applied on the inside surface to seal each seam together.

For smaller-diameter piping, a long strip can be cut to wrap all the way around the entire length of each section of pipe, creating a clean look.

🔧 Rockwool Insulation

Rockwool is a brand of insulation with the added benefit of soundproofing.

It is a very durable material, making it the right choice to insulate HVAC ductwork.

Typically found on the inside of the furnace or air handler plenum, it keeps noise and air leaks to a minimum while not slowing down airflow too much.

🔧 Cross-linked Polyethylene Foam Insulation

Also known as XLPE, polyethylene foam is excellent for insulating sheet metal ducts exposed to the outdoors, as it is weather resistant, and its flexibility allows it to bend and insulate simultaneously.

⭐ Reasons For Insulating HVAC Ductwork

Before choosing an insulation type, you should understand the reasons why that type of duct insulation would be used.

Air passing through your home’s duct system often encounters problems.

This can be especially true in the upper attic, which often doesn’t get heated or cooled.

If you haven’t had your ducts cleaned in a while, dirt, dust, and moisture from your attic can enter gaps in any uninsulated air ducts and cause contaminate your HVAC equipment.

The benefits of a properly insulated duct system include improved indoor air quality, which leads to a quieter, more efficient HVAC system, and a reduction in utility bills.

⭐ How To Insulate Ductwork

Let’s start with the basics

Any homeowner can insulate their HVAC ductwork.

All you need is thermal insulation, access to your HVAC ductwork, duct adhesive, foil tape, or duct wrap.

🔧 Duct and Insulation Construction

Before adding any insulation to your HVAC ductwork, you need to determine where each seam is located.

A seam is a point where one section of duct butts up to the next section.

Often these sections are joined with a cleat, and these cleats are air leak points.

These air leaks should be patched before applying any insulation with either a mastic tape or duct sealing compound.

After those joints are covered, the rest of the ductwork can be insulated with fiberglass, Rockwool, or XLPE duct insulation, depending on the application.

🔧 Insulation Failure, WHY?

Aside from aging, the most common reason duct insulation starts to fail is human-caused.

Due to how fiberglass insulation is woven, it is imperative it retains its thickness.

This means no squishing, crushing, flattening, sitting, or stepping on the insulation before or after it is installed.

When a depression is made, cold temperatures can enter that one spot easier, and the only way to fix it is to cut it out and apply more insulation, then seal with so air doesn’t get in.

🔧 What Else Hurts Insulation

Water can also ruin duct insulation, which is common in outdoor rooftop units or walk-in refrigeration coolers and freezers.

But one way water can enter residential insulated duct systems is through condensation.

Although not common, if an air gap is allowed to exist at the same point as a duct seam, the difference in temperature of the air inside the duct vs. the air trapped between the outside surface of the duct and the inside surface of the insulation can create condensation.

This will seep into the fiberglass and ruin it from the inside out.

The bottom will end up sagging due to the weight put on the wrap, and if there’s a tear or a hole in the top side insulation seam or duct wrap, it can pool up and spill over the edge.

🔧 Ok, So The Insulation Is Wet. What’s the Big Deal?

Other than looking unpleasant, the cost of unnecessarily replacing your duct wrap insulation every few years can certainly add up.

However, the most important reason to stop fiberglass insulation from getting wet is the presence of mold spores and corrosion.

Mold spores grow when there’s no airflow, lots of moisture, and no way to kill bacteria, such as UV light.

Indoor air quality is a large subject in its own right, and a simple search can find lots of information.

But we know that mold can and most likely will infiltrate your house if mold grows in and around the air duct system.

It usually starts to grow on walls and ceilings first, so if you see mold in those places, it is time to investigate your duct insulation after removing the mold.

Related Reading: The Complete Guide on How to Improve Indoor Air Quality in Your Home

🔧 How to Inspect?

Alright, you’ve found sagging, wet insulation.

Luckily no mold spores have appeared inside your home, but you’re still concerned about possible corrosion affecting your ductwork.

The best thing to do is visually inspect as much of your duct insulation as possible.

If you see a section that you feel needs to be replaced, you’ll need some materials and basic hand tools.

Start by having a garbage bag ready, and use a pocket knife to carefully cut open any duct wrap that is not contaminated.

Throw away that piece and be careful not to breathe in any insulation, as this can have serious health effects later in life.

At this point, you can inspect the duct for corrosion and wipe it down to clear off any dust.

If the duct is good to go, cut a new piece of either duct board or fiberglass wrap, whichever you took off, and apply some mastic to the inside of one edge to help it stay in place while you wrap the duct.

Try to make a nice straight cut to make it easier to apply duct mastic or tape when you’re ready to seal the new piece on.

And that’s it. It’s kind of like wrapping a present, only larger.

Just take precautions when installing the insulation to not breathe in any fiberglass or let mastic get all over your clothes.

Related Reading: Homeowners Guide to Ductwork Sealing

Related Reading: Ductwork Installation Guide For Homeowners

⭐ Conclusion

So there you have it, what kind of duct insulation is used, why it needs to be replaced, and how to replace it yourself.

This is definitely one aspect of the HVAC trade that the homeowner can feel relatively comfortable doing themselves.

Of course, if they would like a professional HVAC tech to come in and do it, most service companies would be happy to send someone out to quote the job.

Want to learn more about your home’s HVAC system? Feel free to check out our other HVAC articles!