⭐ How a Reversing Valve on a Heat Pump Works!

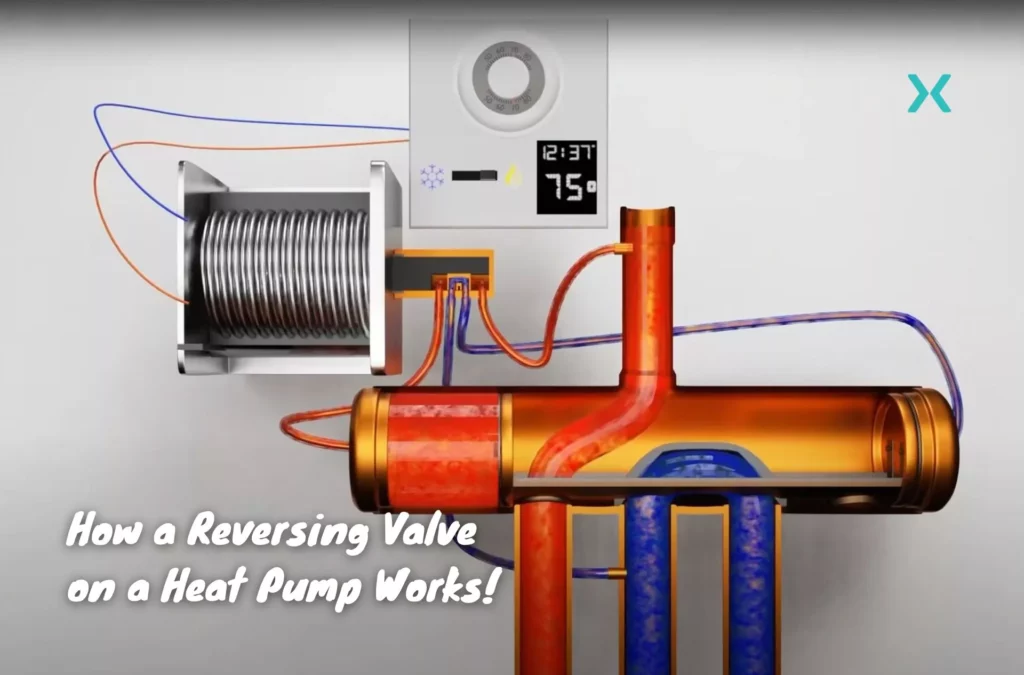

Heat pump systems act like air conditioning systems with a reversing valve to redirect the refrigerant flow to the outside condensing coil from the discharge line in summer.

The reversing valve can redirect that refrigerant flow towards the indoor evaporator coil, making it the condenser coil for heating purposes in winter.

If you need help understanding how a heat pump works, it’s best to read this article first: How Does a Heat Pump Work?

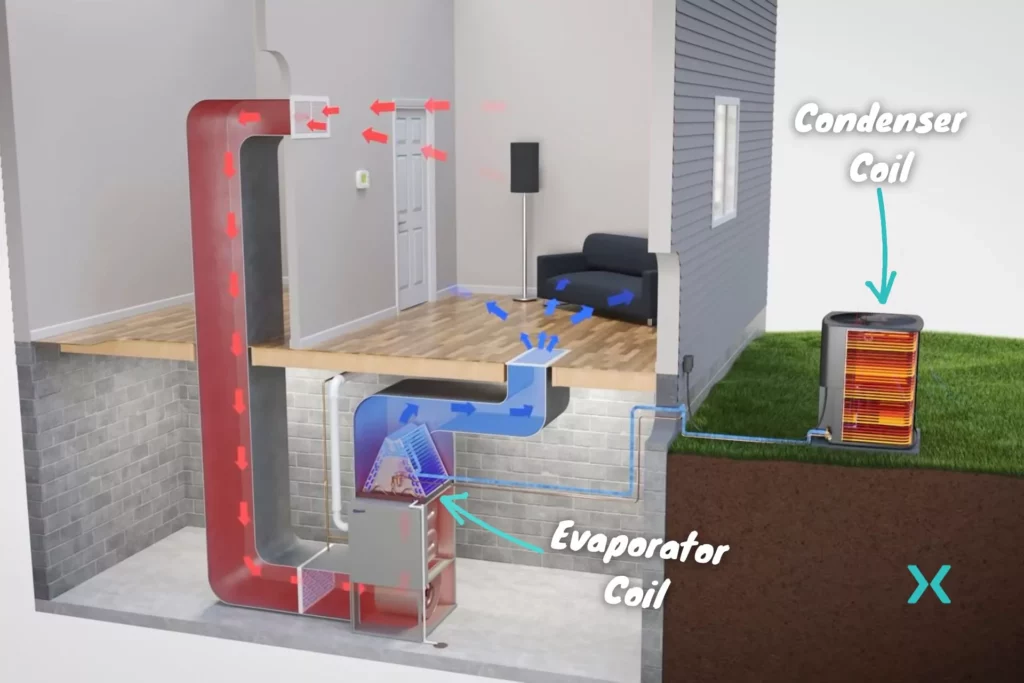

In addition to the heat pump reversing valve, most heat pumps have two separate metering devices. One inside and one outside.

The outdoor metering device is used for the heating cycle in winter when the outdoor coil is now the evaporator coil. The indoor metering device monitors the cooling mode during summer when the indoor coil plays its usual role as the cold side of the air conditioner.

Table of Contents

⭐ How a Heat Pumps Reversing Valve Works!

🧊 Heat Pump Reversing Valve

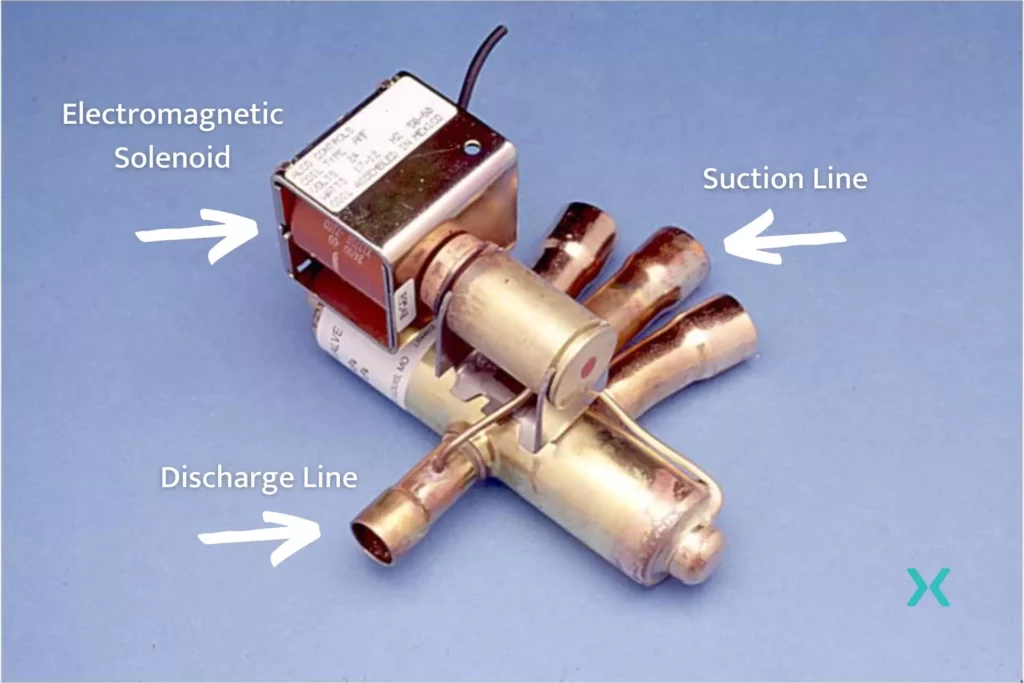

The reversing valve is made up of two primary parts.

The valve, which looks like a small cylindrical metal component directs the flow of refrigerant within the heat pump.

Secondly, you have the suction line and discharge line, which allow for the movement of the refrigerant to and from the reversing valve.

The heat pump reversing valve is sometimes called a changeover or a 4-way valve.

The refrigerant from the compressor discharge (high pressure) is directed into the top of the valve.

The valve has four ports, tube-like fingers protruding from the cylindrical body.

First, the top port receives the refrigerant from the discharge line.

Then, depending on whether the reversing valve is energized or de-energized, the other 3 ports on the bottom direct the refrigerant.

Which ports are active depends on whether the heat pump is in heating or cooling mode.

The center port on the bottom is always the suction line.

The sliding mechanism in reversing valve slides allows the refrigerant to flow to the correct coil.

This allows the suction gas to be rediverted.

Reversing valves work with the help of another component called an electromagnetic solenoid which operates the slider.

🧊 Electromagnetic Solenoid

Generally, when the solenoid is energized, the heat pump works in cooling mode sending the discharge gas to the outdoor coil.

Many manufacturers use this as the standard setup.

However, some manufacturers (such as Rheem or Ruud) may operate in reverse, so it’s best to call in an HVAC professional before working on a heat pump.

When the electromagnetic solenoid energizes, it slides over a pilot valve which acts as a small reversing valve inside the reversing valve.

It redirects the flows creating a pressure differential on one side of the valve, which forces the slide over to operate in cooling mode.

An extra note is that it isn’t the electromagnet that drives the heat pump reversing valve but the pilot valve that uses the pressure created by the compressor to slide the valve.

This is important because if your compressor isn’t pumping correctly, the reversing valve will not shift.

This is because the valve does not cause the valve to shift; it’s the pressure of the refrigerant in the discharge line from the compressor.

So the pressure difference between the discharge and suction lines is what slides the valve into the correct mode.

When the heat pump unit is switched off, the heat pump reversing valve will not shift between heating mode and cooling mode when the pressure differential is equalized.

⭐ How the Indoor and Outdoor Coils Operate

The indoor coil becomes the condenser coil in heating mode, which acts as a heat rejector.

The outdoor coil becomes the evaporator coil, which is now the heat absorber.

You pick up heat from the outside and reject it inside in this mode.

This creates a heating effect for the occupants in the home.

The compressor in a heat pump continues to operate the same as a standard air conditioner, which is to move the refrigerant through the system.

However, the reversing valve interrupts those flows and redirects them in either direction based on the heating and cooling mode.

⭐ A Heat Pumps Suction and Discharge Lines

Heat Pump reversing valves are typically designed with four lines leading to them, with one line at the top and three at the bottom.

Some people call a reversing valve a four-way valve, but if you do not want to get looked at sideways, just stick with calling it a reversing valve.

The four lines can be a bit confusing to understand, so the first place to start is to know which lines are the common suction and discharge lines.

The operation of these common lines stays the same whether the system is in AC mode or heat pump mode.

The common discharge line always leaves the compressor and usually goes to the top of the heat pump reversing valve.

Heat pumps use a suction line to get refrigerant back to the compressor.

This line on a heat pump is routed to the center of the bottom of the reversing valve.

On each side of the common suction line are copper lines used for either suction or discharge, depending on whether the system is in heating or cooling mode.

⭐ How a Reversing Valve on Heat Pump Works

A reversing valve uses a 24-volt electromagnetic solenoid to activate a smaller pilot valve which uses compressor force to drive the reversing valve back and forth, changing the flow of refrigerant, allowing you to operate your heat pump as an AC in summer, and a heater in the winter months.

For homeowners looking to change modes, it’s as easy as hitting a button on your dual-mode thermostat to reverse refrigerant flow.

If you have a heat pump that’s not working correctly or want to learn more about heat pumps, then don’t hesitate to find out if Phyxter Home Services is in your area.

Related Reading: Heat Pump vs Furnace – The Pros and Cons of Each Heating Type

Want to learn more about your home’s HVAC system? Feel free to check out our other Heat Pump articles!